Industry Insights

Online Sources

07 Jan 2026

views (

)

Damion Robotics Unveils World’s First Force-Touch Feedback Teleoperation Data Capture System DM-EXton2 at CES 2026

At CES 2026 in Las Vegas, Damion Robotics (Shenzhen) unveiled the DM-EXton2—the world’s first teleoperation data acquisition system with integrated force and tactile feedback. This breakthrough addresses a critical bottleneck in AI-driven robotics: the scarcity of high-quality, physically grounded interaction data needed to train general-purpose, autonomous robots.

As CES evolves from a traditional consumer electronics showcase into a proving ground for embodied intelligence, Damion’s launch signals a strategic pivot toward foundational infrastructure for robot learning. The DM-EXton2 captures multidimensional human operation data—including motion, force control, and haptic sensations—during remote manipulation, effectively transforming human expertise into “physical intuition” that machines can learn from and generalize.

“While the internet is rich in text and images, it lacks the ‘feel’ and ‘force’ of real-world interaction,” said a Damion representative. “The path to general robot intelligence is shifting from ‘reading ten thousand books’ to ‘walking ten thousand miles.’ Our system enables robots to acquire embodied skills through human-guided experience.”

Building on its predecessor’s strengths—ultra-low latency, high precision, and cross-platform compatibility—the DM-EXton2 features enhanced ergonomics and structural design, significantly improving operator comfort and ease of use.

A key innovation lies in its modular end-effector adaptability. With a tool-free, snap-on quick-change mechanism, users can switch between handheld controller mode and wearable glove mode in seconds. This flexibility supports common humanoid robot end-effectors such as grippers and dexterous hands, enabling “one system, multiple tasks” and lowering deployment barriers across diverse applications.

The standout feature, however, is its real-time force and tactile feedback. During teleoperation, operators receive immediate haptic cues about contact pressure, object compliance, and grip intensity. This allows precise handling of fragile items, delicate insertion tasks, or soft-object manipulation—even when visual feedback is obstructed. Operators can intuitively judge an object’s texture, stiffness, or contact state through touch alone, dramatically improving task success rates and the quality of collected training data.

Beyond the DM-EXton2, Damion showcased a suite of vision-tactile perception hardware at its CES booth, drawing strong interest from global robot OEMs, researchers, and media. On-site demos were continuously booked, with attendees engaging deeply on data pipeline integration, hardware compatibility, and real-world deployment scenarios.

Damion Robotics was incubated at the Hong Kong University of Science and Technology (HKUST), co-founded by Professor Yu Wang—founding dean of HKUST’s Robotics Institute and a globally recognized authority—and Dr. Jianghua Duan. The team combines world-class academic research with proven experience scaling technologies to billions in annual revenue.

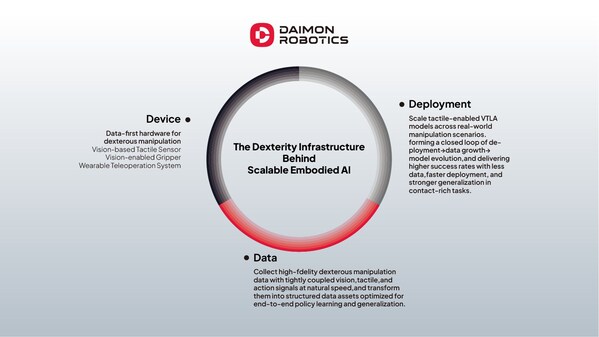

Guided by its “3D Strategy”—Device (vision-tactile hardware), Data (multimodal interaction datasets), and Deployment (scenario-specific rollout)—Damion aims to build the foundational infrastructure for embodied intelligence. Through a DaaS (Data as a Service) model and its proprietary VTLA (Vision-Tactile-Language-Action) framework, the company seeks to deliver scalable, generalizable robotic dexterity—enabling machines to truly understand and act in the physical world.

Source: Damion (Shenzhen) Robotics Technology Co., Ltd.